.jpg)

GF 2

Grillo Čeona kosa

|

Grillo GF 2 Kohler 3000- 358.980,00

Grillo GF 2 Honda GX200 - 420.000,00

The Grillo GF2 is a perfectly balanced sickle bar. Engine and P.T.O. are positioned in such way that thanks to the ground clearance obtained it is ideal for cutting on slopes.

The centre of gravity was designed to ensure manoeuvrability and safety in the most demanding working conditions.

The three gears can all be used whilst mowing.

The Grillo GF2 is fitted with an active cone clutch, a device which ensures remarkably the operator’s safety.

The wide choice of cutter bars ensures meets the requirements of all operators.

The numerous accessory range attached by means of a quick coupling, make the GF2 a multi-purpose machine! |

The standard cutter bar is model “Tirol” with a 115 cm width and crank action.

It is ideal for cutting all grass types and can be used in rustic areas, fruit orchards and grass for animal feed.

The crank mechanism is built using premium steel types and is fitted with grease nipples on all articulating parts.

The floating grass disperser is mounted on anti-vibration rubbers with a special profile to dispel the grass in the most demanding conditions; the grass is cut, dropped to the ground by the action of the wheels allowing easier control when moving forwards.

The blade sections are made of special steel and fixed with special 6 mm length rivets..

The cutter bar’s teeth are made of a special profile to ensure a perfect cut and are made of special heat treated steel.

The blade tensioners are adjustable ensuring so a constant fit between blade and teeth. |

|

|

The 117 cm double blade central cutter bar with its action has a mulching cut mode and is fitted with two blades moving in opposite direction. This “scissor like” cutting action considerably reduces the vibrations on the handlebar when mowing, ensuring an optimal quality cut in all conditions.

Because of its characteristics the double central cutter bar of 117 cm is ideal for cutting in rustic areas, fruit orchards or to obtain grass for animal feed.

The floating grass disperser is mounted on anti-vibration rubbers with a special profile to dispel the grass in the most demanding conditions; the grass is cut, dropped to the ground by the action of the wheels allowing easier control when moving forwards.

The premium quality blades are made with special heat treated steel and the blade tensioners made of a flexible material ensure contact between the two blades. |

The normal central cutter bar of 110 cm has a crank action and quick coupling.

It’s the specific cutter bar for mowing and obtaining grass for animal feed.

The crank mechanism was built with premium steel types and is fitted with grease nipples on all articulating parts.

The floating grass disperser is mounted on anti-vibration rubbers with a special profile to dispel the grass in the most demanding conditions; the grass is cut, dropped to the ground by the action of the wheels allowing easier control when moving forwards.

The cutter bar’s teeth are have a special profile for a perfect cut and are made of special heat treated steel.

The blade tensioners are adjustable ensuring constant contact between blade and teeth. |

|

|

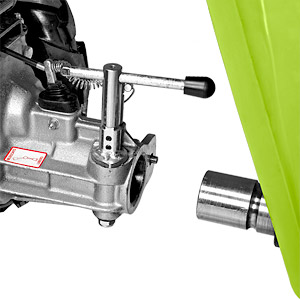

The GF2’s quick coupling allows the change of implements without ever unscrewing any nut. By operating a practical lever you unlock the quick coupling mechanism allowing you to replace other implements. It’s an easy-to-do procedure that you can do without any efforts. |

| The GF 2’s weight distribution was designed to ensure stability when mowing on slopes. To further increase the stability on slopes you have the possibility to increase the track by up to 24 cm with the wheels extensions. The agricultural profile tyres ensure high grip and the handlebar can be adjusted laterally. |

|

|

The GF2’ mechanic transmission with its gears in an oil bath are located inside the carter made of pressed aluminium. The lever operated gears and P.T.O. are easily reachable.

The active cone clutch operates the drive, when leaving the handlebar the sickle bar will immediately stop whilst the engine remains running. In order to further increase the operator’s safety, the drive lever is equipped with a double control to avoid any involuntary actions. The double control can be activated with only one hand. |

The GF2’s gearbox has 3 forward and 3 reverse gears is designed to obtain the optimum speeds for mowing, i.e. 1.1, 2.6 and 4.3 km/h, when fitted with the “Tractor” wheels 4.00-8.

For a level cut, the cutter bar has to be free to incline adapting itself to the ground’s unevenness.

The handlebar was mounted on vibration-proof elements which dampen the vibrations also laterally.

The handlebar is laterally adjustable in order to work more easily on slopes and can be adjusted in height in order to meet the user’s requirements. Furthermore it is reversible and can be lowered to considerably reduce the machine’s size.

All controls are in a comfortable position, including the handlebar’s adjustment levers. |

|

|

The GF2 is fitted with either a Robin Subaru EX17 OHC petrol engine, the Honda GX160 OHV petrol engine or a Lombardini 15LD225 diesel engine; all these models have recoil start and are fitted with the latest technological innovations ensuring easy starting, reliability, low emissions, reduced consumptions, high performance and vibrations which are reduced to the minimum. Grillo GF2 engines are fitted with rear bumper. |

| Grillo have implements available to enhance the GF2’s usefulness, such as a 50 cm rotary cutter with blade brake and, for winter, a 100 cm orientable snow blade as well as a 60 cm two stage snow thrower. |

|

|

The GF2, as all products by Grillo, was projected and built to last and keep its value for many years.

All components, from the simplest to the most complex are of a high quality standard.

Grillo fits only the best engines of the world on its machines!

The GF2 passed very stringent tests to prove the reliability of its drive system, cutter deck, chassis and of all other components.

Handlebar, gears, carter, all are built by Grillo in Italy using premium materials and cutting edge technology. All this to achieve constant and 100% controlled high level quality. |

Painting of Grillo machines consists of a double electrostatic powder coated process. At the beginning there are the washing baths and the preparation, then a first protective coat is applied together with the baking in the oven, turns out to be the best basis for the application of the finishing. The second coat consisting of varnish and a further baking in the oven at 190°C convey the characteristic hardness and brilliance.

All GF2 have been mounted with care for every detail and tested scrupulously by specialised personnel. Final inspection means also machine with started-up engine in order to check the functionality. This is a further and final guarantee for a high quality product. |

|

| All Grillo products are distributed and serviced by a widespread Grillo specialist dealer net. Spare parts remain available also after a lot of years. |

|

|

Motor |

Honda GX200 OHV

Potezni starter

Zapremina motora 196 cc, 1 Cilindar

Snaga motora 5,5 HP (4.1 kW)

Vazdušno hlađenje

Filter vazduha u uljnoj kadici |

|

| |

Motor |

Kohler 3000 Series OHV

Potezni starter

Zapremina motora 196 cc, 1 Cilindar

Snaga motora 5,5 HP (4.1 kW)

Vazdušno hlađenje

Filter vazduha sa promenljivim kertridžima |

|

Kapacitet rezervoara |

3,6 L mot. 3000 Series - 3,1 L mot. GX200 |

|

Prenos |

Zupčanici u uljnoj kadici |

| |

Menjač |

3 brzine napred + 3 rikverc |

| |

Kvačilo |

Konus aktivno |

|

Standardna kosa |

Centralna kosa TIROL, širina kose 115 cm sa aktivnom radilicom [cod. 9L7811 998211] |

|

P.T.O. |

965 rpm u kontra smeru kazaljke na satu |

|

Točkovi |

Pneumatski traktor točkovi 4.00-8 (fiksni disovi) i 16x6.50-8 (fiksni diskovi) |

|

Rukohvat |

Podešavanje po visini i levo-desno. Postavljene na anti-vibracionim blokovima |

| |

Bezbednost |

Aktivno konusno kvačilo prema zakonu |

|

Težina |

95 kg |

|